Built environment professionals have reiterated the need to explore alternative local options, improve investment in research, and halt over-reliance on imported building materials.

They also proposed the opening of land borders for the importation of materials and increased local production of essential building materials to encourage self-sufficiency in the country.

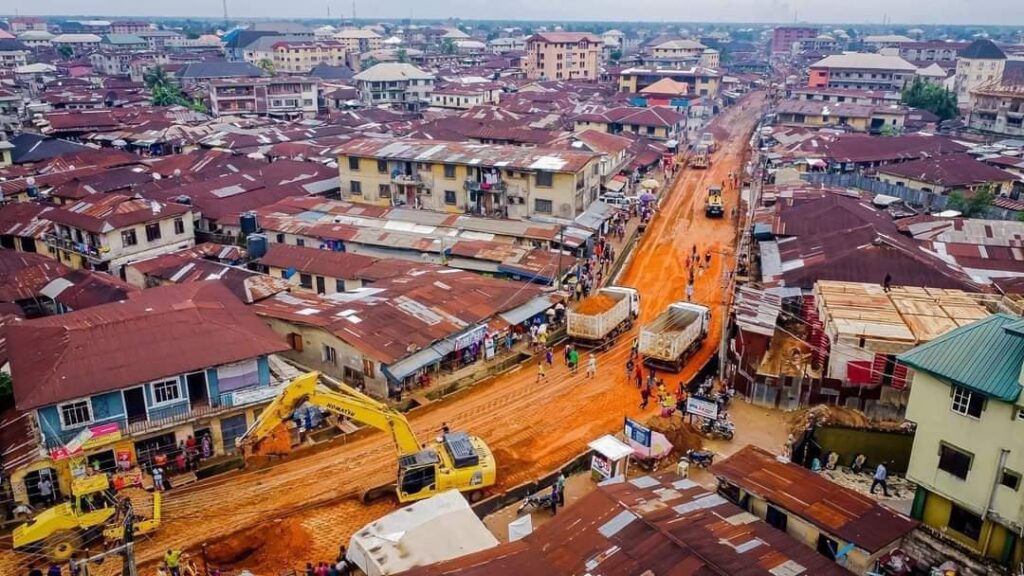

The Guardian’s recent survey shows an alarming surge in prices of essential building materials across the country, which has negatively impacted the entire construction industry value chain. Most of the materials such as cement, iron rods and finishing products have been affected by inflation in the building materials market, making it difficult for contractors and developers to raise appropriate quotations for contracts.

For instance, the price for a 50-kilogramme bag of cement hovers between N7,500 and N8,500. The costs of sand, earthwork, and iron rods are also high in the market. For cement-based blocks, a nine-inch block is N750, while a six-inch block goes for N650.

There has also been fluctuation in the prices of paints and iron rods. For instance, the 8mm previously sold for N518,000 per tonne is now N1,550,000, 10mm that used to cost N520,000 goes for N1,800,000, while the 12mm and 16mm rods sold for N515,000 is now N1,500,000. Also, the 20mm and 25mm earlier sold for N530,000 are now going for N1,800,000, depending on the location.

Former Chairman of the Nigerian Institute of Building, Lagos chapter, Mr Adekanmbi Adelaja, attributed the rising cost of building materials prices to a lack of innovation, and government investment, as well as competition among major distributors in the country.

He highlighted the urgent need for collective action and policy changes to address systemic issues facing the construction industry and mitigate adverse effects on professionals and the people. “If those prices are lesser in other countries, why is it expensive when manufactured in Nigeria,” he queried.

The past Chairman, Nigerian Institute of Quantity Surveyors (Lagos Chapter), Jide Oke, said the current economic situation reflects challenges in the construction sector due to the heavy reliance on imported building materials and foreign inputs.

“The depreciation of the local currency has led to escalating prices, affecting ongoing projects and causing delays in new constructions. Addressing these issues falls under the responsibility of the Federal Government, particularly through the Central Bank of Nigeria (CBN), which needs to implement policies to stabilise the currency and control inflation.

“Furthermore, the scarcity of skilled labour, including artisans from neighbouring African countries, contributes to increased labor costs. President Bola Tinubu’s efforts and the recent Infrastructure Fund Act are steps toward revitalising the sector, but significant challenges remain from the previous administration,” Oke added.

MEANWHILE, building materials retailers said their major concern is the fluctuation in prices, which has impacted their profit margins and ability to maintain competitive pricing. Additionally, the lack of sales due to the high prices has led to decreased revenue.

They are also encountering difficulties in sourcing materials due to disruptions in supply chains or restrictions on imports.

Mr Philip Maduka, an iron retailer said the fluctuation in prices has impacted profit margin and ability to maintain competitive prices, while a cement retailer, Mrs Mariam Abiodun, said the increase in the price of cement distorted the market.

“I’m feeling a bit relieved now that the price has dropped to N7,500 from the factory. It means I can offer better deals to my customers and attract more businesses. If this trend continues, we will see more stability in the market,” she added.