The Chief Technical Officer of Huawei for South Africa, Matamela Aubrey Mashau, has said cutting-edge technology and Artificial Intelligence (AI) can help Nigeria and other oil and gas producing nations around the world increase oil production, efficiently manage energy transition and rapidly recover from the economic impact of the COVID-19 pandemic.

He said this at a roundtable on the sidelines of the recently-concluded MWC Technology summit in Barcelona, themed:“MWC Media Roundtable Briefing (Oil & Gas)” organised by Huawei, a leading global technology and equipment provider, to showcase its Oil & Gas solutions to industry stakeholders.

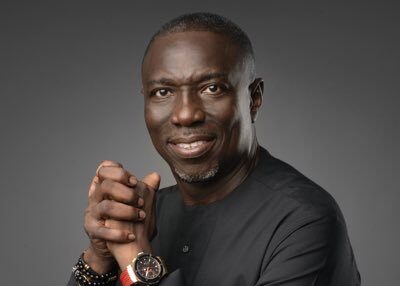

Also in attendance at the roundtable included Yumna Audu, Head of Business and Information Technology from Nigeria’s NLNG and Sana Lallali from Sonatrach among others.

Mashau, in his presentation, said digital and intelligent technologies are becoming the forces that drive the transformation of the oil and gas sector.

He told stakeholders that the use of distributed fibre sensing and AI technologies are ideal for buried pipelines that are impossible for manual or drone inspection.

At the MWC media roundtable, the summit disclosed that Sonatrach and Huawei collaborated to build a joint innovation centre that produced the smart oil and gas pipeline inspection solution which it said aims at further strengthening oil exploration in Nigeria.

This solution, according to Mashau and Sana Lallali, Manager Sonatrach Joint Innovation Centre, uses cutting-edge technologies to minimise operations and maintenance costs, proactively alert pipeline deterioration, and promptly find fibre cuts.

“During E&P, we need to process a massive amount of seismic data. Generally, the original data of a single unit is dozens of terabytes (TB), sometimes reaching the petabyte (PB) level. Moreover, there are dozens of steps to data processing. Cloud technology enables us to quickly deploy seismic data processing, interpretation, and E&P software, which boosts E&P and operational efficiency.

“Take the most time-consuming prestack depth migration processing as an example. The processing time can be shortened from 19 days to 55 hours, boosting efficiency by 830 per cent” Mashau said.

On her part, Audu, who is NLNG’s Head of Business and IT Services, said the gas company of Nigeria should be equipped with future-oriented and forward-looking IT systems.

To achieve this, she revealed that NLNG partnered with Huawei and deployed its high-quality Wi-Fi 7 APs on the nation’s campuses.

Audu said: “With upgraded wireless experience, application experience, and O&M experience, we strongly believe that we are capable of building campus network benchmarks in the global oil and gas industry.

“In our office, the speed of Huawei’s Wi-Fi 7 APs reached 3.16 Gbps in actual tests. This impressed us. In our golf club, we planned to deploy two APs, while only one Huawei Wi-Fi 7 AP is enough to achieve full signal coverage and high-speed access. Besides, these APs are highly compatible with our devices on the live network. Therefore, we are satisfied with the test results.

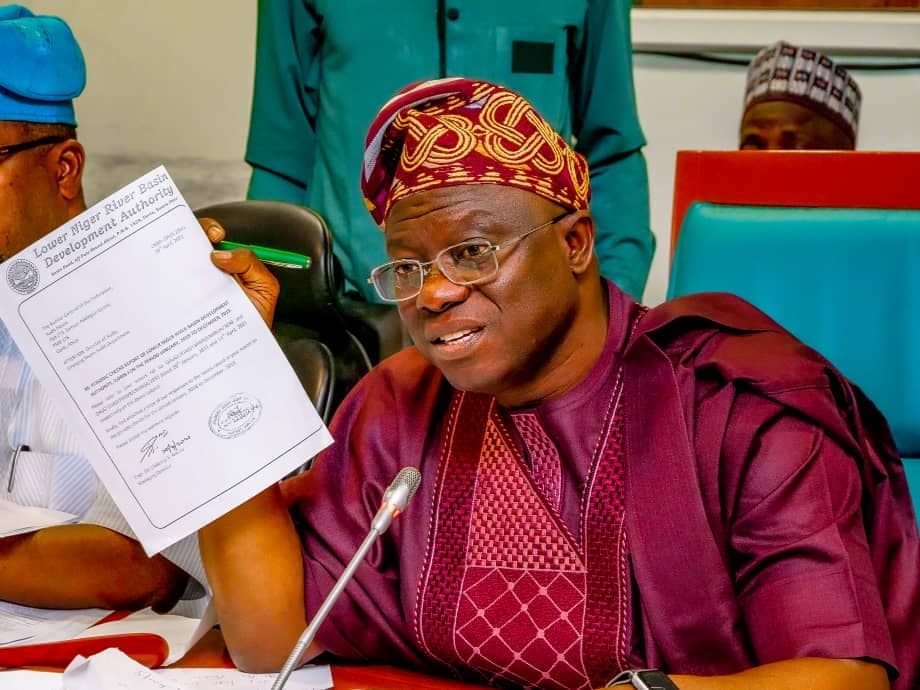

Lallali, who is the manager of Sonatrach Joint Innovation Centre, a national state-owned oil company in Algeria, announced that its country has about 43 oil and gas pipelines, accompanied by 14,000 km of optical cables.

The official also noted that while traditional manual inspection is costly and inefficient, it can be difficult to obtain the pipeline running status anytime in real-time.

Lallali said: “We innovated the fibre sensing inspection solution together with Huawei. This solution is based on Huawei’s pipeline fibre warning solution and live-network service management process.

“When external construction occurs around a pipeline, the optical fibre deployed along the pipeline collects vibration information and transmits the information to the optical sensing device deployed in a station or BVS equipment room, thereby achieving precise positioning.”